From Ted Metcalfe – a longish read but well worthwhile and thoughtful as always …

We’re not good at sharing stories in the Australian pipeline industry, and in my opinion that is a weakness we should address.

I recently drafted the short article which is now available on AS2885.info, setting out some examples of how awareness of unplanned outcomes has already influenced the continuing improvement of the AS2885 suite of Standards.

My objective with this post is to initiate a conversation in order to identify what level of interest there may be in sharing stories, and maybe even development of an online repository of information about unplanned outcomes in the world-wide pipeline industry with particular focus on lessons learned relevant to Australian pipelines.

Why Share Stories?

The value of articulating lessons learned for the benefit of others has been well-known for many years.

In his 1998 book “What Went Wrong? Case Histories of Process Plant Disasters” it was Trevor Kletz, (the man who invented the HAZOP process), who set out five very good justifications for sharing stories, paraphrased here as:

- Moral – If we have information that might prevent an accident, then we have a duty to pass that information on to others who face similar circumstances.

- Pragmatic – If we tell others what we have learned, they may return the favour by similarly informing us about what they have learned.

- Economic – In a competitive world, if we tell others about things we have done to prevent further accidents, they may spend as much as we have to protect themselves.

- Industry Perspective – If one company has a serious accident, the entire industry suffers loss of public esteem, and any new legislation arising will affect the whole industry, driving up costs.

- Impact – Nothing reads and sticks like an accident report. Mere cautionary guidance is easily forgotten, but we will remember reading about the consequences of getting it wrong.

Sharing stories is just another form of communication and collaboration, which James Trevelyan emphasises as important for the engineering profession in his book The Making of an Expert Engineer.

For me personally, my interest in sharing stories derives from reading a book many years ago called “Set Phasers on Stun” by Stephen Casey. It’s a collection of short accounts of many different disasters, all caused in some way by human error or by failures in design of the man-machine interface. There have been many more similar disasters since the book was written in 1998, so I hope he does an update.

Since then, I have read extensively about failures of complex engineered systems. The human error component contributing to those failures has prompted even more reading about how people think and make decisions. I have reviewed over fifty failure events overseas and in Australia in pursuing this hobby.

Yes, I admit to being hooked on “disaster porn”, but I believe that with increased awareness of things that have gone badly wrong, I have learned a lot about what works and what doesn’t work in design and operation of complex engineered systems.

Why are we reluctant to share stories?

We are all aware of stories which probably ought to be shared with others.

How do I identify what stories ought to be told? When I hear about something that went wrong, I just put myself in the position of those directly involved and ask the question:

“If I were in their shoes, would I do things that way again?”

If the answers that come to mind are “probably not” or “hell no!”; then the story should be shared so that the lessons get passed on to others.

Until recently in the pipeline industry there has not been widespread support for story-telling as a means of passing on knowledge, but the EPCRC researchers documented some research around story-telling as a learning tool indicating positive benefits from doing so.

Our Pipeline Operators Group maintains a reasonably complete database of incidents of damage to pipelines in the Australian pipeline industry, and from conversation with those administering that database it is clear that some operators are reluctant to admit “own goals”.

Similarly, poor outcomes or failures in project execution are embarrassments, too often hidden, and so the lessons are not learned by others.

In previous conversations about this concept, others have often expressed concern about getting the facts exactly correct, and a reluctance to identify the parties involved. I take the view that it is not necessary to do either in order to pass on the important lessons in an effective manner.

Another concern often expressed by others has been fear of potential legal repercussions. That’s probably a valid concern.

Readers are invited to respond to this post with comments, feedback, and maybe a story or two; but given that there is some sensitivity around sharing stories, we need some guidelines.

Some guidelines for posting about this topic

If you are sharing a story about Australian events with unplanned outcomes

- Provide enough description about what happened to put the event in proper context.

- Focus on extracting the lessons learned which can help others avoid similar unplanned outcomes.

- Don’t upset anyone by publicly sharing confidential information.

- If the story can’t be written in an anonymous way so that the identity of the companies or personnel involved is protected, then it probably should not be posted.

The stories can be anything that generates a lesson that pipeliners ought to be aware of. The reasons for unplanned poor outcomes might include any of the following:

- Inadequate competence and experience.

- Inadequate or overly-optimistic planning (both budget and schedule).

- Failure to adequately implement Front End Loading (FEL) practices.

- Over-specification or under-specification in procurement of contracts and services.

- Inadequate consideration of potential outcomes, leading to unexpected consequences.

- Contracting and commercial pressures.

- Poor selection and administration of contracting strategies.

I guess the above list says there’s lots of ways we might get things wrong!

Overseas disasters

There is certainly no shortage of examples of stories about unplanned outcomes in the world-wide pipeline industry.

The USA experience is particularly frightening in this regard. Just go to Wikipedia and search on “List of pipeline accidents in the United States”. It goes on for many pages.

We have all heard about the big ones like San Bruno and more recently Boston, and for events like that there’s lots of links available to formal investigation reports of hundreds of pages each.

Not many people are prepared to wade through hundreds of pages to identify the lessons.

For overseas disasters, what may be more useful for Australian engineers is a brief summary about what happened, why it happened, and how such an unplanned outcome can be prevented.

If there is genuine interest among readers, some of us might be willing to prepare such summaries for others in Australia to read.

Would you like to see a collation of information on each such disaster which summarises what happened and why, and how the lessons learned are relevant for Australian pipelines?

Let us know by posting a response on the blog.

Australia has stories too

We may not have had any similar “disasters” in Australia (yet), but there have been some unplanned outcomes and sub-optimal projects in our pipeline industry, and not all were directly related to pipeline engineering design.

Although it can be argued that project management and contractual matters are not issues of technical competence, it is my opinion that a solid understanding of such matters by pipeline engineers is important, and also that project management decisions ought to fully recognise technical advice prepared by engineers.

Valuable engineering lessons can be learned from study of process plant failures as well.

The triggers for unplanned poor outcomes that I have personally witnessed over many years in Australia include:

- Quality and System Integrity failures.

- Contractual disputes arising from reliance upon lawyers instead of on engineering competence.

- Aggressive cost-cutting.

- Pushing the envelope with new technology or untried procedures.

- Coatings and coating defects generally, and the technical and commercial aspects of long-term Field Joint Coating integrity in particular.

- Circumstances peculiar to the recent CSG-to-LNG Boom in Queensland.

- Acceptance of residual risk when further mitigation ought to have been applied.

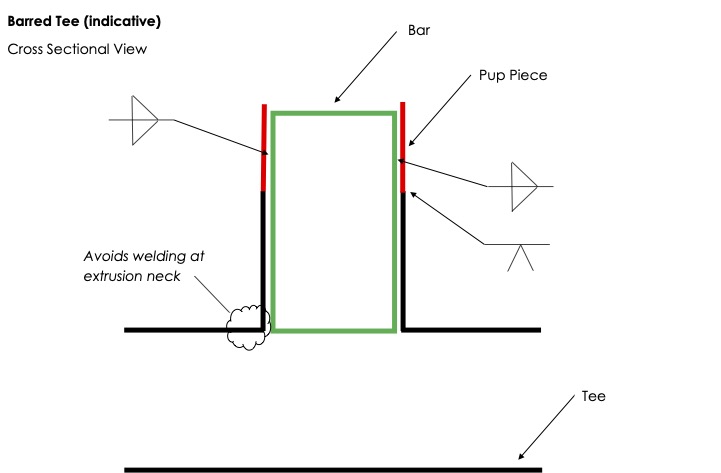

- Inadequate understanding of the technical challenges during design and planning of Horizontal Directional Drills.

I guess this list says there’s a lot of ways we have indeed got things wrong.

Benefits to our industry

Every unplanned outcome hurts our industry in terms of supply reliability or cost or reputation or all of these.

Stories usually have a significant engineering knowledge component which affects asset integrity, and sharing such stories for increased awareness can only improve the safety and reliability of our industry.

In my opinion, if only a fraction of the legal expenses incurred in dealing with unplanned outcomes of the past had been spent instead to assist development of better skills and competence in pipeline engineering, we would be a much-improved industry today.

Over to You

Feedback, comments and maybe a story or two to share with other blog readers are welcome.

If you are keen to read some good disaster porn or better understand how people think and make decisions, I have a long list of recommended reading for you.